|

|

|

|

You are in: Future Technologies : 3D Printing

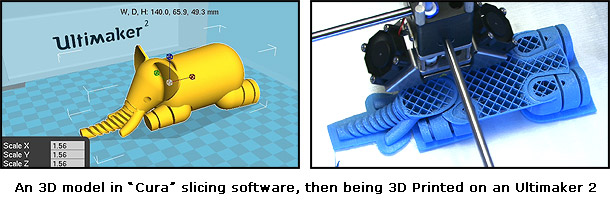

3D Printing

3D printing -- also known as additive manufacturing -- turns digital 3D models into solid objects by building them up in layers. The technology was first invented in the 1980s, and since that time has been used for rapid prototyping (RP). However, in the last few years, 3D printing has additionally started to evolve into a next-generation manufacturing technology that has the potential to allow the local, on-demand production of final products or parts thereof. Already it is possible to 3D print in a wide range of materials that include thermoplastics, thermoplastic composites, pure metals, metal alloys, ceramics and various forms of food. Right now, 3D printing as an end-use manufacturing technology is still in its infancy. But in the coming decades, and in combination with synthetic biology and nanotechnology, it has the potential to radically transform many design, production and logistics processes. This web page provides an overview of 3D printing technologies, as well as their present and likely future application. For a full list of 3D printer manufacturers, bureau services and other market players, please see my 3D Printing Directory. And for 318 pages on the subject, you may be interested in my book 3D Printing: Third Edition. THE RANGE OF TECHNOLOGIES3D printing encompasses a wide range of additive manufacturing technologies. Each of these builds objects in successive layers that are typically about 0.1 mm thin. The methods used vary significantly, but all start with a computer aided design (CAD) model or a digital scan. This is then processed by 'slicing software' that divides the object into thin cross sections that are printed out one on top of the other. You can watch me go through the process in this video.

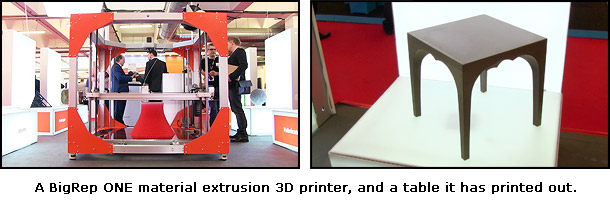

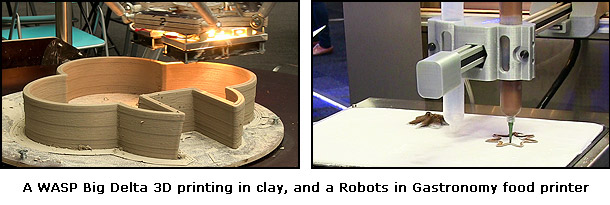

In basic terms there are four categories of 3D printer. Firstly we have printers that extrude a molten or otherwise semi-liquid material. Secondly, there are printers that solidify a photocurable resin. Thirdly, there are printers that bind or fuse the granules of a powder. And finally, there are printers that stick together cut sheets of paper, plastic or metal. Many companies now manufacture 3D printers, a great many of whom have invested significant time and money in developing the exact processes on which their hardware relies. There are therefore a great many 3D printing technologies that sit within the above four categories. For commercial purposes, these technologies have also been given a variety of names. This means that the 3D printing marketplace is awash with acronyms and jargon, with different companies using different terms to refer to the same 3D printing process. In an attempt to introduce some clarity to the 3D printing marketplace, the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have developed various standards. The latest of these was introduced in December 2015, and is called ISO/ASTM 52900. This defines seven 3D printing technologies, which are summarized below. You can also see six of the seven technologies in action as part of my video report from the TCT 3D Printing Show 2014. Material extrusionMaterial extrusion uses a nozzle to extrude a semi-liquid material to create successive object layers. Most usually the 'build material' is a thermoplastic such as acrylonitrile butadiene styrene (ABS), polycarbonate (PC), nylon, or the bioplastic polylactic acid (PLA). Whatever material is used, it is usually delivered to a print head as a solid, thin strand or 'filament' that is then heated into a molten state. Today, material extrusion is the most common 3D printing process. The technology was invented by Scott Crump in 1988, who set up a company called Stratasys to commercialize his invention. Crump chose to name the technology 'fused deposition modelling' or 'FDM', and patented and trademarked these terms. Hence, while many people use the phrase 'FDM' to refer to this kind of 3D printing, only Stratasys actually makes FDM 3D printers. Other manufacturers refer to the same process as 'thermoplastic extrusion', 'plastic jet printing' (PJP), the 'fused filament method' (FFM) or 'fused filament fabrication' (FFF). Consumer material extrusion 3D printers can now be purchased for a few hundred dollars. At the other end of the spectrum, high-end industrial machines -- such as the Stratasys 900mc 3D Production System -- cost hundreds of thousands of dollars and can produce final objects with a comparable quality to injection molded parts. There are now also some very large 3D printers that extrude thermoplastics, including the Big Rep ONE and the Big Area Additive Manufacturing Machine (BAAM) from Cincinati Incorporated. The latter is large enough to fabricate the chassis and body of a full-sized car.

In addition to pure thermoplastics, there are an increasing number of thermoplastic composites that can be 3D printed, including thermoplastics mixed with metals, carbon fiber and carbon nanotubes. As illustrated below, it is also possible to materially extrude concrete, clay and many different kinds of food.

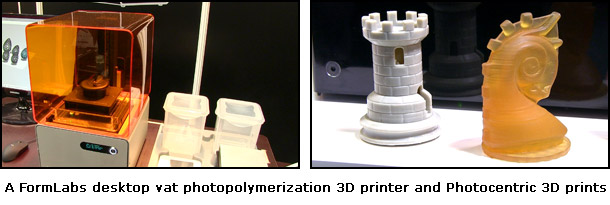

Vat photopolymerizationVat photopolymerization uses a laser or other light source to solidify successive object layers on the surface or base of a vat of liquid photopolymer. The very first commercial 3D printer was based on a vat photopolymerization technique called 'stereolithography'. This was invented by Charles Hull in 1984, who subsequently founded 3D Systems. Stereolithographic 3D printers (known as SLAs) position a perforated platform just below the surface of a vat of liquid photopolymer. A UV laser beam then traces the first slice of an object on the surface of this liquid, causing a very thin layer of photopolymer to harden. The perforated platform is then lowered very slightly and the process repeats until a complete object has been printed out. Another vat photopolymerization technology is 'DLP projection'. This uses a projector to solidify object layers one complete cross-section at a time. One of the leading manufacturers of this kind of 3D printer is EnvisionTEC. Vat photopolymerization 3D printers are expensive to run due to the cost of their photopolymer resins, but offer very high resolutions and deliver excellent surface quality. Until a few years ago, vat photopolymerization 3D printers themselves remained very expensive. However, there are now several manufacturers -- including FormLabs and Photocentric 3D -- who offer this kind of hardware for a few thousand or even a few hundred dollars.

Material jettingMaterial jetting uses a print head to spray liquid layers that are usually then solidified by exposure to UV light. This again offers very high resolution 3D printing, and is even capable of producing multi-colour and multi-material output by spraying several different materials from a multi-nozzle print head in varying combinations. The latest material jetting 3D printer from Stratasys -- the J750 -- can fabricate objects out of six different materials (both rigid and flexible) in up to 360,000 colours, and with a 0.014 mm (14 micron) layer resolution. Material jetting remains an expensive 3D printing technology, but as the images below demonstrate, the results can be spectacular.

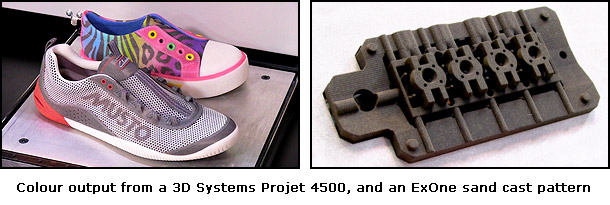

In the near future, a new material jetting technology called 'NanoParticle Jetting' (NPJ) is due on the market. Developed by Xjet (who also developed the above material jetting technology now owned by Stratasys), this jets solid metal nanoparticles within a liquid suspension, so allowing inkjet-style technology to directly 3D print highly detailed metal parts. You can see a great video about this innovation here. Binder jettingBinder jetting uses a print head to selectively spray a binder (or in other words glue) onto successive layers of power. Many binder jetting 3D printers spray coloured inks as well as the binder onto their powder layers, so allowing them to produce full colour output. Most commonly the powder used in binder jetting is a gypsum-based composite that needs to have its surface coated after printout if a robust object is required. However, the ProJet 4500 from 3D Systems builds full-colour objects from a durable plastic powder. Yet other binder jetting hardware can build objects by sticking together sand or powdered metals. Where a binder is sprayed onto sand, the final object is used as a sand cast mold or pattern, into which molten metal is poured. Once the metal has cooled solid, the sand is then broken away.

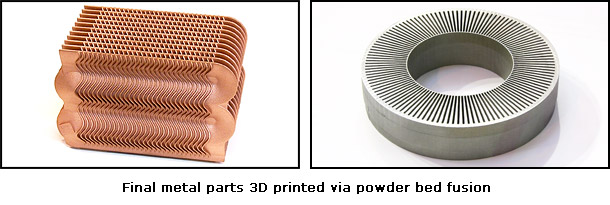

Binder jetting metal printing has been developed by a company called ExOne (who also make 3D printers that binder jet sand cast molds). Here a layer of bronze, stainless steel or Inconel powder is laid down and a print head moves across it to selectively spray on a binder solution. A heating lamp then dries the layer, a fresh layer of powder is rolled over it, and the process repeats. Once all layers have been output, the object is then placed in an oven to fully cure the binder. At this stage the object is still very fragile, but is put in a kiln where it is infused with additional metal powder. The final result is a very solid object that is a least 99.9 per cent solid metal. You can see the results of this amazing process in my Online 3D Printing video. Powder bed fusionPowder bed fusion uses a laser, electron beam or other heat source to selectively fuse successive powder layers. The technology goes by a great many proprietary names, including 'laser sintering' (LS), 'selective laser sintering' (SLS) 'direct metal laser sintering (DMLS), 'selective heat sintering' (SHS), laserCUSING and 'electron beam melting' (EBM). Build materials range from plastics -- such as nylon -- to metals that include aluminium, copper, steel, nickel alloys, cobalt chrome, iron, titanium and high performance Inconel alloys. It is also possible to create objects using new composite materials such as 'alumide', which is a powdered mix of nylon and aluminium.

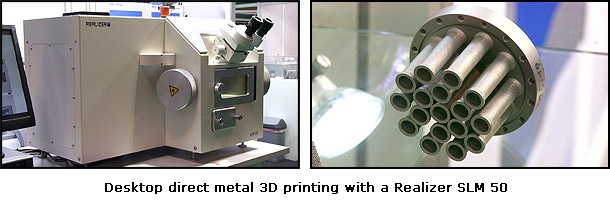

Powder bed fusion is currently both expensive and complex to master. Even so, the technology is starting to be used to produce very high quality industrial parts, including fuel injectors and other aerospace and rocket components. It is also already possible to produce small metal parts on the desktop using a Realizer SLM 50 powder bed fusion 3D printer.

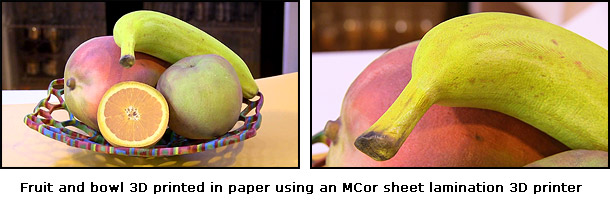

Directed energy depositionDirected energy deposition uses a laser or other heat source to fuse a powdered build material as it is being deposited. Unlike in powder bed fusion, here the powdered build material is deposited from a nozzle into a high power laser or electron beam that fuses it into solid metal. Build materials include steel, copper, nickel and titanium. The technology is also unique in that it can be used not only to create new parts, but also to fuse metal back on to existing parts, such as worn or otherwise damaged turbine blades. Unfortunately I have never had this technology or its output before a camera, and so cannot include a picture here. Sheet laminationSheet lamination sticks together sheets of cut paper, plastic or metal. For example, 3D printers manufactured by Mcor create their output from standard reams of copy paper that can also be sprayed with colour inks to create incredibly detailed colour models, such as the bowl of fruit illustrated below. Meanwhile, Fabrisonic use an ultrasonic welding process to fabricate objects from sheets of metal foil.

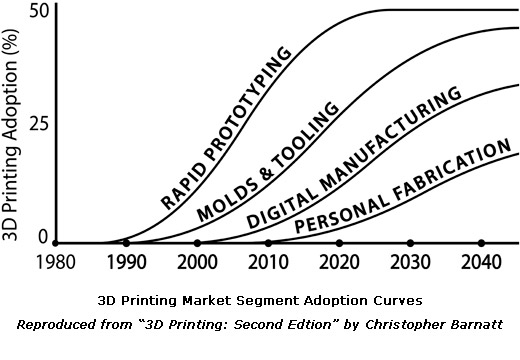

THE RANGE OF APPLICATIONSThe 3D printing industry already serves four quite distinct market segments, all of which are at different stages of maturation. As illustrated in my diagram below, the most mature market for 3D printing involves the production of prototypes. Next, and growing very rapidly, we have the use of 3D printers to fabricate the molds and other tooling from which final products are made. After this comes direct digital manufacturing (DDM) -- or in other words, the use of 3D printers to make final products or parts thereof. And finally we have the very new market for personal fabrication.

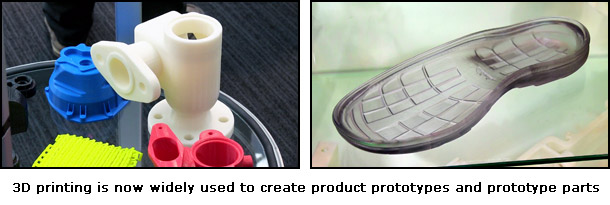

3D printing rapid prototypesSince the late 1980s, 3D printing has been used to create prototypes and concept models. These can significantly speed and otherwise assist design and pre-production processes, and as a result can save companies a great deal of money as well as improving the function of final products. Material extrusion 3D printers costing a few thousand and even sometimes a few hundred dollars can now make decent prototypes in many situations. More expensive 3D printers based on material jetting or powder bed fusion can now also produce highly detailed, functional prototypes out of a wide range of materials, and increasingly in full colour. There is even already a 3D printer -- the DragonFly 2020 -- that can 3D print prototype circuit boards.

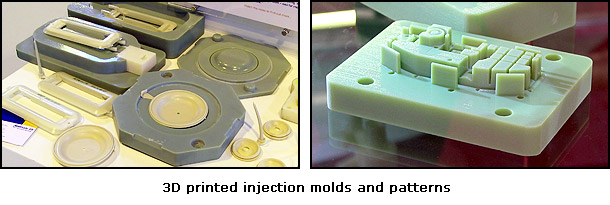

3D printing molds and other toolingThe fastest growing area of 3D printing application is the additive manufacture of production tools. Traditionally, the molds, patterns, jigs, fixtures and other tooling used to make final products has been hand crafted at very significant cost. For example, the molds used to create plastic parts often costs tens of thousands of dollars. In contrast, it is now possible to use 3D printers to produce low-run injection molding masters for hundreds of dollars, and final high-run mold masters for a few thousand. The impact of 3D printing on traditional production processes can therefore be dramatic.

As mentioned above under 'binder jetting', it is also now possible to directly 3D print sand cast cores and molds. Traditional sand casting requires wooden patterns to be crafted, around which casting sand is packed. The wooden pattern then needs to be removed from the resultant mold or core (not always an easy or successful operation), before molten metal is poured in to cast the final part. By using 3D printers (such as the S-Max+ from ExOne) to manufacture sand cast molds and cores, companies can spare themselves the cost of crafting wooden pattern masters. They can also cast more intricate parts from sand molds that would be impossible to fashion by traditional means. Once again time and cost savings can be very significant. For example, as ExOne highlight in this case study, 3D printing sand cast molds and cores can cut weeks from production times, as well as delivering cost savings of over 80 per cent. Also increasingly being used in traditional metal casting processes are 3D printed substitutes for 'lost wax' patterns. Here 3D printers based on material extrusion or vat photopolymerization produce wax-like objects that are later surrounded by a traditional casting material (such as plaster of Paris). The resultant mold is then heated, the wax-substitute melts and is drained away, and molten metal is once again introduced into the mold. The use of 3D printed lost-wax-substitute patterns is especially popular in jewelry or other industries that make small, low-run, intricate metal parts -- and especially as it is now possible to purchase high-resolution vat photopolymerization 3D printers from a few hundred dollars upwards. Direct Digital Manufacturing (DDM)According to the American Society of Manufacturing Engineers, direct digital manufacturing (DDM) refers to the 'the process of going directly from an electronic digital representation of a part to the final product via additive manufacturing'. On occasion, some such final products may be molds or other items of tooling as mentioned above. However, in industrial sectors including space, aerospace, automotive manufacture, healthcare, toy making, art-and-crafts, designer goods and fashion, we are starting to witness the application of 3D printing to directly fabricate final products or parts thereof. The drivers of the DDM Revolution are multitudinous, and include the ability to use 3D printing to optimize the geometry of final parts (often saving raw materials in the process); to make parts with geometries that could not be created via traditional means; and to make low-run, highly customized products that would be not cost effective to manufacture without 3D printing. 3D printing is also a technology that can help to improve sustainabilty via increased localization. Right now, many of the companies dominating DDM are in the space and aerospace sector. For example, SpaceX has already flown one its its Falcon 9 rockets with a 3D printed main oxidizer valve, and is using powder bed fusion to 3D print the engine chambers for its forthcoming Crew Dragon manned space capsule. In more mainstream aviation, Airbus is now incorporating 3D printed components into its aircraft, with its latest A350 XWB containing over 1,000 3D printed components. Meanwhile GE Aviation's new CFM LEAP jet engine incorporates several 3D printed parts. Most notably, these include one component that would be impossible to make using conventional manufacturing methods. Over in the automotive sector, 3D printing is now widely employed to make parts for F1 racing cars. More startlingly, a company called Local Motors is intending to launch a vehicle called the LD3M Swim that will be 'around 75 percent 3D printed by volume'.

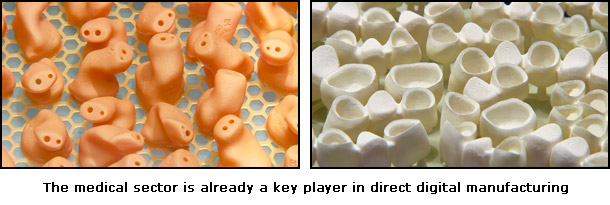

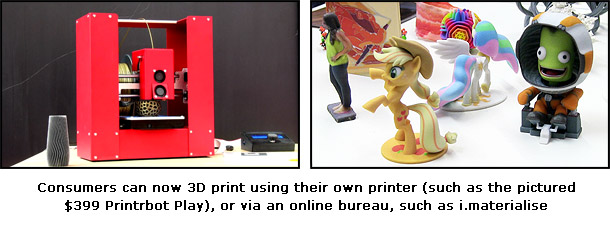

In the space, aerospace and automotive sectors the key advantages of 3D printing are to optimize component geometries, to save expensive materials, and to reduce the cost of low-run production. In contrast, in the healthcare sector a more important benefit is customization. Already, at least in the United States, 3D printing is enabling 'digital dentistry', with dental appliances starting to be routinely 3D printed based on patient scans. Hearing aid shell manufacture is also being transformed by 3D printing -- as evidenced by the batch of customized hearing aid shells shown on the left hand pane of the above image. 3D printing is additionally starting to be used in the manufacture of other, far larger custom prosthetics, as well as in surgical planning. You can see and learn far more in my Medical 3D Printing video. Right now, other notable pioneers of direct digital manufacturing include producers of jewelry, designer goods and toys. To get a feel of their work, just visit the websites of sculptress Bathsheba Grossman, design studio Nervous System, and producers of 3D printed toys and gifts ThatsMyFace.com. Personal FabricationIn some respects the market for personal 3D printing is now growing very rapidly, with over a million personal 3D printers likely to be sold annually by 2020. However, the kinds of object that can currently be fabricated on personal hardware are extremely limited. Despite fulfilling the dreams of some enthusiasts, personal 3D printers are therefore a product category in a very, very early stage of development, with hardware that will allow mainstream consumers to fabricate a wide range of products unlikely to arrive on the market for a decade or more. The above point noted, for those content to produce objects out of thermoplastics or thermoplastic composites, many 3D object repositories now provide access to a wealth of free or for-a-free 3D models for download-and-print. To many people's surprise, it is already perfectly possible to visit a website such as Thingiverse and to download a replacement part for your car dashboard, or a new lens cap for your camera. These can then be printed out at serviceable quality on a domestic 3D printer that costs under $1,000. For manufacturers and suppliers of spare parts, this is a quite alarming development! Even before personal 3D fabricators able to print complex products become available, 3D printing is just starting to facilitate a new age of personal fabrication in which anybody can get their digital designs turned into material reality, and even offered for commercial sale. Empowering this revolution are a host of 3D printing bureau services that allow anybody to upload or otherwise supply a digital file that is then 3D printed. As most bureaus operate at scale, they can afford to purchase and operate a wide range of 3D printers, hence allowing individuals to fabricate a far wider range of objects in broader range of materials than possible on domestic and prosumer hardware. Bureaus such as Shapeways and i.materialise additionally allow people who have uploaded 3D models to open an online store from which their goods can be sold. This allows anybody to get into the manufacturing business without any investment in stock or production tooling. Rather, the 3D printing bureau takes the customer's order, produces the product, ships it, and provides a revenue share to the designer.

For those who want to get something printed out but who do not own a 3D printer, there is now also a great service called 3D Hubs. This connects 3D printer owners to others locally seeking a printout, and allows the latter to upload 3D files, and the former to earn some money printing them out. Already around 30,000 3D printer owners are part of the 3D Hubs network, so providing over a billion people with a local, community-based 3D printing service. WHAT REVOLUTION?Whether or not they arrive en-mass in the home, 3D printers have many promising areas of potential future application. They may, for example, be used to output spare parts for all manner of products, and which could not possibly be stocked as part of the inventory of even the best physical or even online store. Hence, rather than throwing away a broken item (something unlikely to be justified a decade or two hence due to resource depletion and enforced recycling), faulty goods will be able to be taken to a local facility that will call up the appropriate spare parts and simply print them out. 3D printers may also be used to make future buildings. Demonstrating the potential, over in China an amazing company called WinSun Decoration Design Engineering has already 3D printed a number of houses. Produced using a vast material extrusion 3D printer, these include a 1,100 square meter mansion and a five storey apartment block. Another future application is the use of 3D printers to create replacement organs, and even to directly repair the human body in situ. This is known as bioprinting, and is an area of rapid development. You can learn more on the bioprinting page, or see more in my bioprinting video or the Future Visions gallery. Back in late 2012 and early 2013, 3D printing caught the world's imagination, with many proclaiming that it would trigger the Next Industrial Revolution. To the bizarre dismay of the popular press, such a revolution did not arrive within the next 18 months. Many people subsequently not only lost interest, but decided to dismiss 3D printing as no more than hype. The above is extremely sad, as very significant 3D printing technology developments continue to accrue. Large companies also continue to enter the marketplace, and nobody promised an additive manufacturing revolution overnight. Absolutely 3D printing is not doing to replace all forms of traditional manufacturing, and no serious pundit has ever suggested so. But within twenty years -- and possibly within less than ten -- the digital manufacturing capabilities of 3D printing and related technologies are set to have a transformational impact on the direct or indirect production of a reasonable proportion of products, and hence on a great many individuals and organizations. More information on 3D printing can also be found in my book 3D Printing: Third Edition, and in my 3D Printing videos You can also locate a wide range of 3D printer manufacturers, resellers, bureau and other services in my 3D Printing Directory. . Return to Future Technologies. Return to 3D Printing Resources.

|

Learn in more my latest 3D Printing book  3D Printing Directory RELATED VIDEOS Medical 3D Printing TCT Show 2015 3D Printshow 2015 The Next Big Thing TCT Show 2014 3D Printing: The Business Opportunities Top 3D Printers 2014 3D Printshow 2014 Top 3D Printers 2013 3D Printing Revolution 3D Printshow 2013 3D Printshow 2012 Online 3D Printing Bioprinting iMakr 3D Printer Store 3DP and Peak Oil  Understand 3D printing in context in The Next Big Thing |

|

|